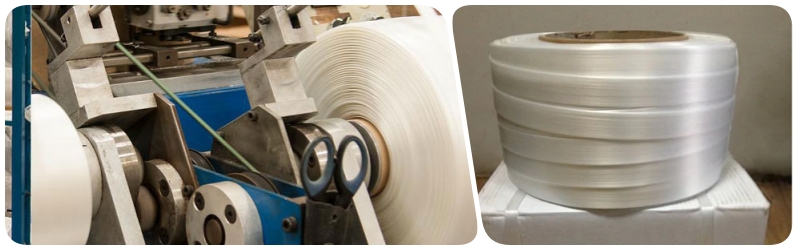

In today’s fast-paced global trade environment, ensuring that goods are securely transported is a top priority for manufacturers, logistics companies, and importers alike. Among the tools used to safeguard cargo, composite strap has emerged as a critical solution, especially for heavy-duty applications. Known for its strength, flexibility, and durability, composite strap offers numerous advantages in the transportation of heavy goods across diverse industries.

**Strength and Durability**

One of the most important characteristics of composite strap is its exceptional strength. Designed to withstand the tension and stress associated with the transport of heavy cargo, composite strapping can securely hold large, bulky items in place. Compared to steel or polypropylene strapping, composite strapping offers a unique balance of high tensile strength while maintaining flexibility, making it ideal for irregularly shaped or compressible cargo. This feature is particularly valuable in industries that deal with heavy equipment, large construction materials, and even automotive parts.

Composite strap is also highly resistant to environmental factors, such as UV rays, moisture, and temperature fluctuations. This means that even when cargo is exposed to harsh conditions during long transit periods, the integrity of the strapping remains intact, minimizing the risk of damage or collapse.

**Cost-Effective and Efficient**

While steel strapping has traditionally been the go-to option for securing heavy cargo, composite strap offers a cost-effective alternative without sacrificing performance. Steel is prone to rust and corrosion, which can compromise the security of the load. In contrast, composite strapping is rust-resistant, lightweight, and requires less maintenance. The lighter weight also makes it easier to handle and apply, reducing labor costs and increasing operational efficiency.

The flexibility of composite strap also ensures that it can absorb impacts during transportation without breaking or damaging the cargo. This reduces the need for additional padding or protective materials, further saving costs and simplifying packaging.

**Safety and Sustainability**

In addition to its practical benefits, composite strap contributes to improved safety in the handling and transportation process. Unlike steel strapping, which can snap or break under tension, potentially causing injuries, composite strapping is safer to handle and apply. It does not have sharp edges, making it less likely to cause cuts or abrasions during installation or removal.

From an environmental standpoint, composite strap is a more sustainable choice. Many manufacturers produce composite strap from recycled materials, and the strapping itself can often be recycled after use, aligning with global efforts to reduce plastic waste and promote circular economy principles.

**Versatile Applications Across Industries**

The versatility of composite strap has made it an essential tool for various industries. It is commonly used in sectors such as construction, shipping, logistics, and manufacturing, where large and heavy items need to be transported over long distances. Whether securing timber, metal pipes, or machinery, composite strapping provides the reliability and strength necessary to ensure that goods arrive at their destination intact and undamaged.

In conclusion, as global trade and heavy cargo transportation continue to grow, the demand for reliable, cost-effective, and safe packaging solutions will only increase. Composite strap stands out as a key tool in meeting these demands, offering a combination of strength, durability, and flexibility that makes it ideal for heavy-duty applications.