In the ever-evolving world of industrial packaging, efficiency, durability, and cost-effectiveness are paramount. One key player in achieving these goals is the Bale Press Strap Extrusion Machine. As the demand for robust and reliable packaging solutions continues to grow across various industries, these machines have emerged as essential tools for manufacturers worldwide. Understanding their significance can shed light on why they are indispensable in modern packaging processes.

### What is a Bale Press Strap Extrusion Machine?

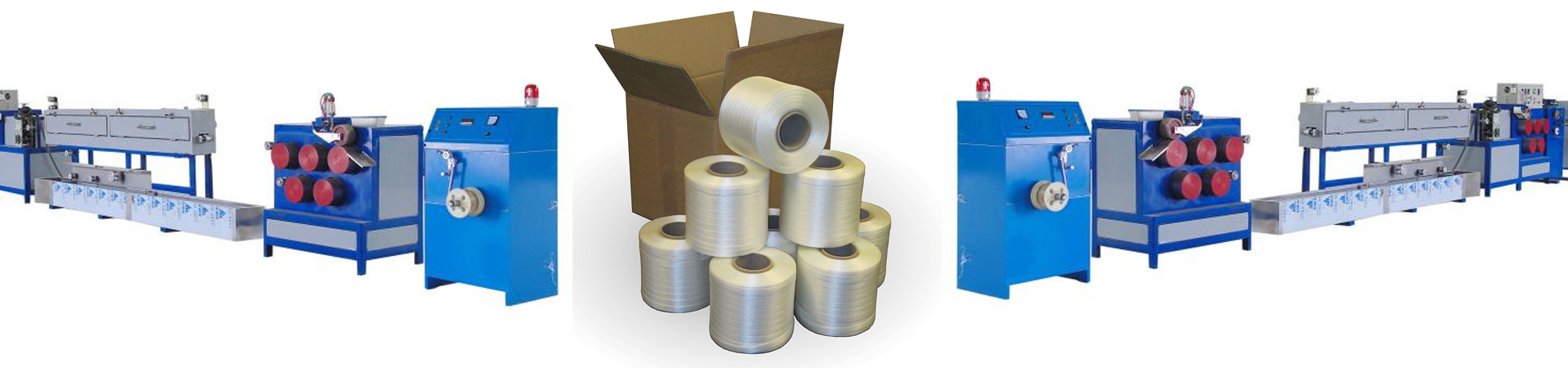

A Bale Press Strap Extrusion Machine is a specialized piece of equipment used to produce high-strength plastic straps, commonly known as bale straps. These straps are widely used to secure bales of materials such as paper, textiles, hay, and recyclables. The machine extrudes plastic, typically polypropylene (PP) or polyester (PET), into thin, flexible, and strong straps that can withstand substantial tension and pressure.

### Enhancing Packaging Efficiency

One of the primary reasons for the importance of Bale Press Strap Extrusion Machines is the efficiency they bring to the packaging process. Traditional methods of securing bales involved the use of ropes or metal wires, which were labor-intensive, time-consuming, and often less secure. With the advent of these machines, manufacturers can produce large quantities of uniform, high-quality straps in a relatively short period, significantly speeding up the packaging process.

The automation provided by these machines also reduces the need for manual intervention, leading to fewer errors and more consistent results. This efficiency is particularly crucial in industries where large volumes of goods need to be packed and shipped daily, such as in recycling centers, agriculture, and logistics.

### Cost-Effectiveness and Sustainability

Cost is a critical factor in any manufacturing process. Bale Press Strap Extrusion Machines contribute to cost savings in several ways. Firstly, the materials used in strap production, like PP and PET, are relatively inexpensive and widely available. This lowers the overall cost of producing the straps compared to alternative methods. Additionally, these machines are designed for high output with minimal waste, further reducing costs.

Sustainability is another significant advantage. As industries worldwide move towards greener practices, the ability of these machines to produce recyclable and reusable straps makes them an environmentally friendly option. PET straps, in particular, can be recycled multiple times without losing their strength, aligning with global efforts to reduce plastic waste and promote circular economies.

### Enhancing Product Safety and Integrity

Product safety during transport and storage is a top priority for manufacturers. Bale Press Strap Extrusion Machines produce straps that are incredibly durable and resistant to breakage, ensuring that the bales remain securely fastened. This strength is essential for maintaining the integrity of the goods, preventing damage during handling and transportation.

The consistency in the quality of the straps produced by these machines also plays a vital role in maintaining product safety. Each strap is extruded to precise specifications, ensuring uniform thickness and strength. This uniformity translates to better performance in securing loads, reducing the risk of accidents caused by strap failure.

### Versatility Across Industries

The versatility of Bale Press Strap Extrusion Machines is another reason for their growing importance. They are used across a wide range of industries, from agriculture, where they secure hay and straw bales, to recycling, where they bundle paper and plastic waste. Their ability to produce straps of varying widths, thicknesses, and tensile strengths makes them adaptable to different applications, catering to specific industry needs.

### Conclusion

In conclusion, Bale Press Strap Extrusion Machines have become an indispensable part of modern packaging processes. Their ability to enhance efficiency, reduce costs, promote sustainability, and ensure product safety makes them a crucial asset for manufacturers across various industries. As the demand for reliable and eco-friendly packaging solutions continues to rise, the importance of these machines will only grow, cementing their role as a cornerstone of industrial packaging.