In the evolving landscape of industrial packaging, ensuring the safe and secure transport of goods is paramount. Traditionally, materials like steel and PET (Polyethylene Terephthalate) strapping have dominated the market due to their strength and durability. However, the advent of composite strapping has introduced a new, superior alternative that promises enhanced performance and numerous benefits. This article explores the myriad advantages of using composite strapping in modern packaging applications.

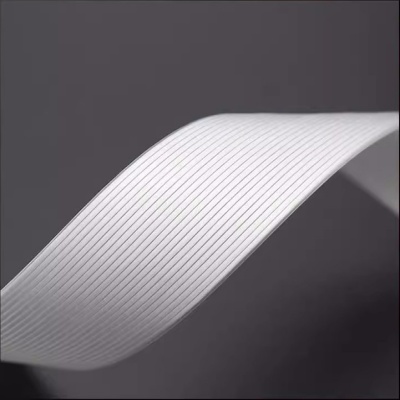

One of the most significant benefits of composite strapping is its remarkable strength. Composite straps are often referred to as "synthetic steel" because they combine high-tensile polyester filaments with a polymer coating. This construction endows composite straps with a high pulling force, often exceeding that of traditional PET straps. This superior strength ensures that even the heaviest and most cumbersome loads can be securely fastened, reducing the risk of load shifting during transit.

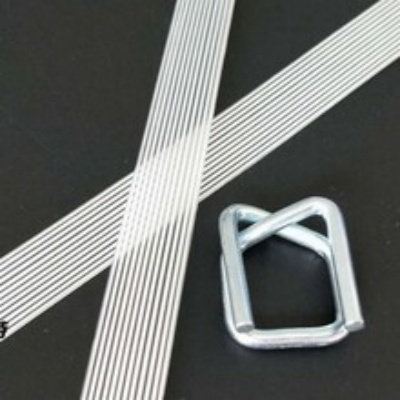

Composite strapping offers exceptional flexibility, which is a critical advantage over more rigid strapping materials like steel and PET. This flexibility allows composite straps to conform to irregularly shaped loads, ensuring a snug and secure fit. The ease of use is further enhanced by the fact that composite straps are lighter than their steel and PET counterparts, reducing the physical strain on workers during application. The use of simple tensioning tools, often required for composite strapping, makes the packaging process quicker and more efficient.

he durability of composite strapping is another standout feature. The polyester filaments within the strap are protected by a polymer coating, which shields them from environmental factors such as UV radiation, moisture, and temperature fluctuations. This makes composite strapping an excellent choice for outdoor storage and long-term applications. Unlike steel straps, which can rust and corrode, or PET straps, which can degrade over time when exposed to UV light, composite straps maintain their integrity and strength in various conditions.

While the initial cost of composite strapping might be slightly higher than that of PET or steel strapping, the long-term cost savings are significant. The superior strength and durability of composite straps mean that fewer straps are required to secure a load, reducing material costs. Additionally, the reduced risk of load damage during transit translates to fewer product losses and claims, further enhancing cost savings. The lightweight nature of composite strapping also contributes to lower shipping costs, as it adds less weight to the overall package.

Safety is a critical concern in any industrial setting, and composite strapping excels in this area. Unlike steel strapping, which can have sharp edges and pose a risk of injury to workers, composite strapping is much safer to handle. The smooth, flexible nature of composite straps reduces the risk of cuts and abrasions, and their lack of metal components eliminates the risk of rust and corrosion-related injuries. This makes composite strapping a safer option for workers and reduces the need for protective gear during application.

Composite strapping is incredibly versatile and can be used across a wide range of industries and applications. From securing heavy machinery and construction materials to bundling fragile items and consumer goods, composite straps offer a reliable solution for various packaging needs. Their ability to maintain tension and withstand dynamic loads makes them particularly suitable for applications where stability and security are paramount.

In an era where sustainability is increasingly important, composite strapping offers environmental benefits as well. The polyester filaments used in composite straps are often made from recycled materials, reducing the environmental footprint of the packaging process. Additionally, the durability and longevity of composite strapping mean that fewer straps are needed over time, resulting in less waste.

The benefits of using composite strapping in modern packaging are clear. With its unparalleled strength, flexibility, durability, and safety features, composite strapping is rapidly becoming the material of choice for industries seeking efficient and reliable packaging solutions. Its cost-effectiveness and environmental benefits further solidify its position as a superior alternative to traditional strapping materials. As the packaging industry continues to evolve, composite strapping is poised to play a pivotal role in ensuring the safe and secure transport of goods worldwide.