In the dynamic world of manufacturing and logistics, where speed, efficiency, and sustainability are paramount, technological advancements continue to reshape traditional processes. Among these innovative solutions, the Hotmelt Strap Produce Machine stands out as a game-changer in the packaging industry. This revolutionary equipment represents a significant leap forward in securing and optimizing cargo handling, redefining the way products are bundled, transported, and stored.

The packaging industry has traditionally relied on various methods to secure loads, ranging from steel strapping to plastic ties. While these methods have served their purpose, they often come with limitations such as environmental concerns, high labor costs, and potential damage to packaged goods during transit. As global commerce expanded and the demand for faster, safer, and more eco-friendly packaging solutions grew, the need for an innovative alternative became evident.

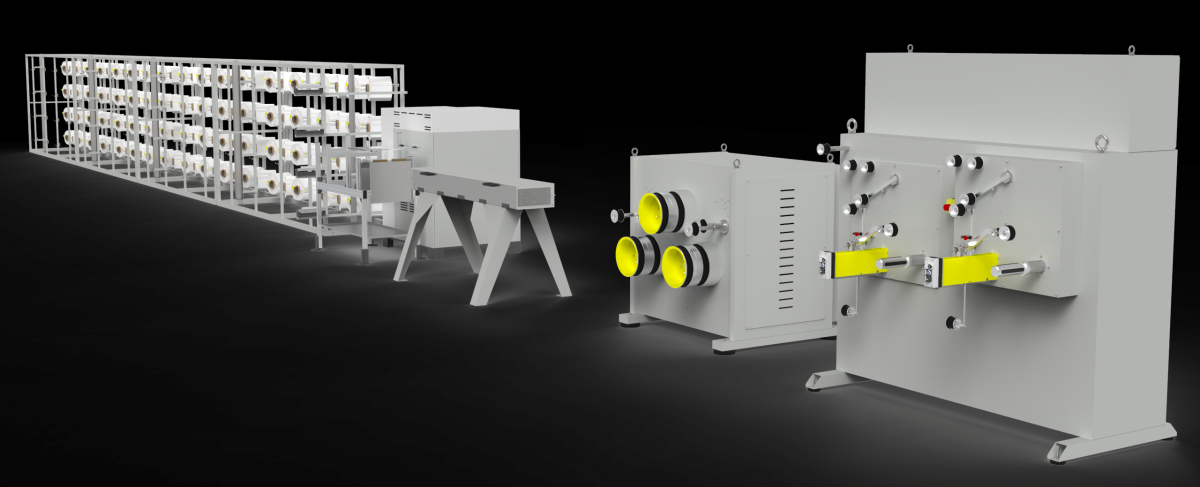

Enter the Hotmelt Strap Produce Machine – a technological marvel designed to address these challenges head-on. This machine leverages the power of hot melt adhesives, a type of polymer-based glue that hardens upon cooling, offering unparalleled strength and flexibility in packaging applications. By automating the application of hotmelt straps, the machine not only streamlines the packaging process but also elevates the overall quality and efficiency of cargo handling.

1.Enhanced Security & Durability: Hotmelt straps provide exceptional holding power, ensuring that even the heaviest and most awkwardly shaped loads remain securely fastened during transportation. This robust adhesion system minimizes the risk of package breakdown or content spillage, protecting both products and the environment.

2.Increased Efficiency: Automation is the cornerstone of the Hotmelt Strap Produce Machine's efficiency gains. By eliminating manual strapping processes, labor costs are significantly reduced, while productivity soars. The machine operates at high speeds, applying straps with precision and consistency, allowing businesses to process more goods in less time.

3.Improved Sustainability: In an era where environmental consciousness is paramount, the Hotmelt Strap Produce Machine offers a more eco-friendly solution. Compared to traditional metal or plastic strapping, hotmelt straps are often made from recyclable materials, reducing waste and minimizing the environmental footprint. Additionally, the elimination of manual handling reduces the potential for human error and subsequent packaging waste.

4.Versatility & Customization: The versatility of hotmelt technology allows for a wide range of applications across industries. From palletizing goods in warehouses to securing sensitive electronic components during shipment, the Hotmelt Strap Produce Machine can be tailored to meet specific packaging needs. Moreover, customization options enable businesses to optimize their packaging processes for maximum efficiency and cost savings.

5.Cost Savings: Over the long term, the Hotmelt Strap Produce Machine offers substantial cost savings. The reduced labor costs, coupled with the durability of hotmelt straps that often outlast traditional methods, translate into significant savings for businesses. Additionally, the elimination of frequent strapping replacements and repairs further contributes to the machine's cost-effectiveness.

The introduction of the Hotmelt Strap Produce Machine has had a profound impact on the packaging industry and beyond. It has not only revolutionized cargo handling but also sparked a shift towards more sustainable and efficient packaging practices. As businesses adopt this technology, they are better positioned to compete in a global market where time-to-market and environmental responsibility are key differentiators.

Moreover, the success of the Hotmelt Strap Produce Machine has inspired further innovation in the packaging sector. Manufacturers are now exploring new materials, designs, and technologies that build upon the strengths of hotmelt adhesives, pushing the boundaries of what is possible in packaging solutions.

Ultimately, the Hotmelt Strap Produce Machine serves as a testament to the power of technological innovation in addressing long-standing industry challenges. By offering a secure, efficient, and sustainable alternative to traditional packaging methods, it is reshaping the way we think about and approach cargo handling, setting the stage for a more sustainable and productive future in the packaging industry.