Product Description

Our Paper Strapping Band Extrusion Machine is designed to produce high-quality paper strapping bands with various widths and thicknesses. This machine is equipped with advanced technology for efficient extrusion and cutting of the paper bands, ensuring consistent and reliable performance.

The Features of our Paper Strapping Band Extrusion Machine

1. Versatility: The machine can produce paper strapping bands in different sizes to meet various packaging needs.

2. Cost-effective: Using paper strapping bands is a cost-effective alternative to traditional plastic strapping, making it a sustainable and environmentally friendly option.

3. Easy to operate: The machine is user-friendly and easy to operate, requiring minimal training for operators.

4. High productivity: Our Paper Strapping Band Extrusion Machine is capable of producing large quantities of paper strapping bands in a short amount of time, increasing productivity and efficiency in packaging operations.

5.The strapping tape is recyclable, pollution-free, and meets the national environmental protection requirements;

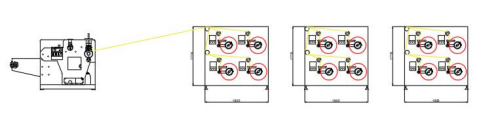

Product Structure

Slitting Machine(1 set):

Ⅰ.Material shaft, 40KG magnetic powder tension control system, deviation correction system, frame, motor, PLC, touch screen. Inverter, sensor and proximity switch light

Ⅱ.Slitting tool configuration: 9mm, 12mm, 15mm

Ⅲ.Dimensions: (approx.) 2400MM*1500MM* 1350MM

Rewinder(3 set):

Ⅰ.Frame, motor, cable motor, PLC, touch screen, sensor and proximity switch light

Ⅱ.Dimensions: (approx.) 1900MM*1450MM* 1870MM

Main functions

1) Side-fitting tape guide, servo motor cable, 5-19MM width paper tape rewinding, select the corresponding bandwidth through the touch screen for rewinding, no need to manually change the transmission gear.

2) After rewinding is completed, the machine stops automatically, the paper tube is replaced manually, the paper tape is cut, and the rewinding operation is carried out.

3) The reel uses the torque mode of the servo motor. The tension during reeling can be set and adjusted through the touch screen, so that strapping tapes of different weights or widths can be reeled with appropriate torque, and the bending deformation of the strapping tape after reeling can be minimized.

4) After reeling, the strapping tape needs to be removed manually and a new paper tube installed.

Note:Paper tube: Ø203mm*(165 - 195)mm paper tube, thickness 5MM, 10MM, recycled worn paper tubes cannot be used.

Summary

In conclusion, our Paper Strapping Band Extrusion Machine is a reliable and efficient solution for producing paper strapping bands for packaging applications. With its advanced technology and user-friendly design, it offers versatility, cost-effectiveness, and high productivity, making it an ideal choice for businesses looking to improve their packaging processes.