The logistics industry plays a vital role in today's globalised business environment. From the transport of raw materials to the distribution of the final product, every step of the way requires efficient, safe and reliable packaging materials to ensure the integrity and security of goods. Against this backdrop, Nine Tripods is emerging as a leader in the logistics industry with its unique Composite Strapping product, leading a revolution in material innovation.

I. Innovative Features of Composite Strapping

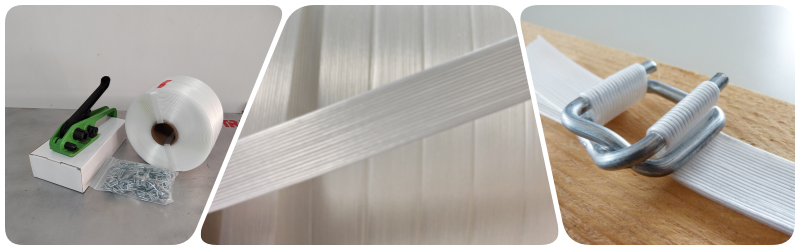

Composite Strapping is a kind of strapping made of composite material. Compared with traditional metal or plastic strapping, Composite Strapping has the following significant innovative features:

High strength and light weight: Composite Strapping is made of advanced composite material technology, which gives the product both high tensile strength and light weight design. This makes it possible to reduce the burden on vehicles and improve transport efficiency in the logistics process.

Corrosion and abrasion resistance: Composite Strapping's composite materials have excellent corrosion and abrasion resistance, and are able to maintain stable performance in a variety of harsh environments. This makes Composite Strapping particularly suitable for marine transport, chemical transport and other specialised areas.

Environmentally friendly and recyclable: Nine Tripods focuses on the concept of environmental protection. Composite Strapping is made from a wide range of recyclable raw materials, which reduces environmental pollution during the production process. At the same time, the product will not produce harmful substances in the process of use, in line with the development trend of the modern logistics industry green.

Ⅱ.The application of Composite Strapping in the logistics industry

Composite Strapping has been widely used in the logistics industry due to its excellent performance and environmental protection concept. Specifically, it is mainly used in the following aspects:

Goods binding and fixing: The high strength characteristics of Composite Strapping make it able to firmly bind and fix all kinds of goods to ensure that the goods will not be damaged by bumps, vibration and other reasons in the process of transport.

Container encapsulation: In container transport, Composite Strapping can be used as sealing tape to improve the sealing and safety of containers. At the same time, its lightweight design also reduces the overall weight of the container and improves transport efficiency.

Special applications: The corrosion and abrasion resistance of Composite Strapping makes it particularly suitable for marine transport, chemical transport and other special applications. In these areas, the traditional metal or plastic strapping often can not meet the requirements, while Composite Strapping can easily cope with a variety of harsh environments.

Ⅲ.Market Outlook of Nine Tripods Company

With the continuous development of the logistics industry and technological progress, Nine Tripods' Composite Strapping products will face a broader market prospect. In the future, Nine Tripods will continue to increase investment in research and development, and constantly optimise product performance and improve production efficiency. At the same time, the company will also actively expand the international market, and cooperate with the global logistics industry to promote the popularity and application of Composite Strapping technology.

In conclusion, Nine Tripods' Composite Strapping products are gradually becoming the new favourite in the logistics industry due to their unique innovative features and wide application prospects. In the future, we have reason to believe that Nine Tripods will create more brilliant performance in the field of logistics materials.